Fly Ash Dryers are indeed designed to handle industrial by-products like fly ash, which are characterized by their low bulk density and potentially high initial moisture content. However, the range of materials they can process extends far beyond fly ash. Leveraging their unique working principle and design, these dryers are also widely applicable for drying materials across multiple industries.

Application Field

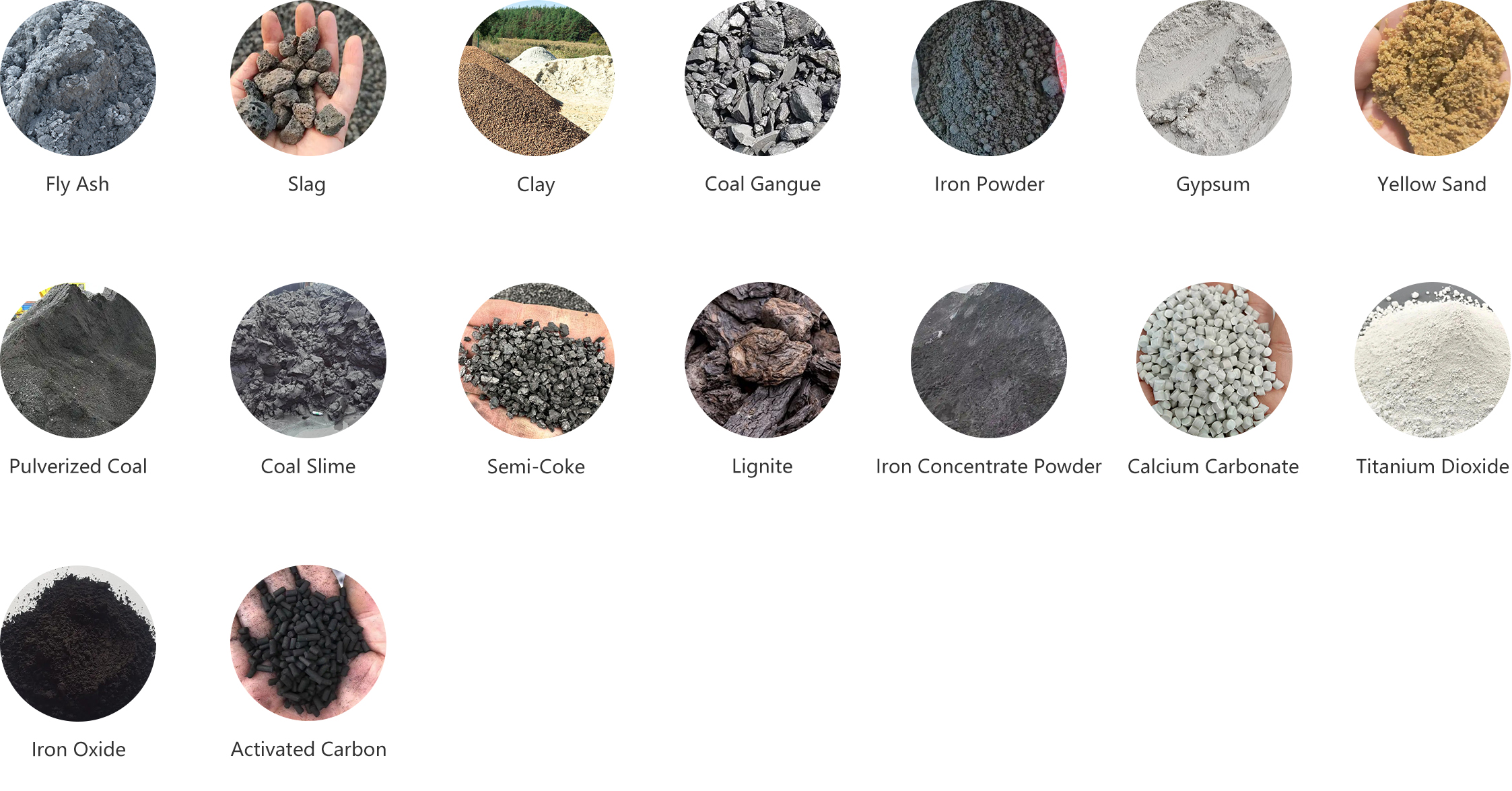

| Application field | Specific material examples | Advantage |

| Building Materials Industry | Fly ash, slag, cement raw materials/additives (such as clay, coal gangue, iron powder), gypsum (including desulfogypsum), yellow sand | The process demands high handling capacity and consistent operation to achieve a low final moisture content (typically ≤1%), ensuring compliance with the formulation and fineness specifications for building material production. |

| Electric Power/Metallurgi- cal Industry | Pulverized coal, coal slime, semi-coke, lignite, various mineral powders (such as iron concentrate powder) | Emphasis is placed on energy conservation and consumption reduction, frequently through waste heat utilization. The equipment must exhibit excellent abrasion resistance and the capability to handle adhesive materials (e.g., coal slime, filter cakes). |

| Chemicals and Others | Chemical raw materials (such as calcium carbonate, titanium dioxide, ferric oxide, iron oxide), activated carbon | There are specific requirements for precise temperature control and high product purity (to avoid contamination). The materials to be processed are generally fine-grained or possess particular physical and chemical properties. |

Parameters

Item | Unit | Model | |||

Φ3.2*8.0 | Φ3.6*8.0 | Φ3.8*10.0 | Φ4.0*12.0 | ||

Diameter of outer cylinder | m | 3.2 | 3.6 | 3.8 | 4.0 |

Length of outer cylinder | m | 8.0 | 8.0 | 10.0 | 12.0 |

Cylinder volume | m³ | 64.31 | 81.39 | 113.35 | 150.72 |

Cylinder speed | rpm | 4-10 | |||

The initial moisture content of fly ash | % | 20-25 | |||

Water content of fly ash | % | ≤2 | |||

Max inlet temperature | ℃ | ≤950 | |||

Capacity | T/H | 20-25 | 25-35 | 40-50 | 50-55 |

Motor | Y132-S-4 | Y160-M-4 | Y160-M-4 | Y280-S-4 | |

Power | Kw | 11*4 | 15*4 | 90 | 110 |

Reductor | XWD7-23 | XWD7-23 | ZSY315-‖ | ZSY355-‖ | |

Reductor ratio | 29 | ||||

Structural composition

• Drying cylinder:

It is the core component, usually made of metal materials, with good heat resistance and sealing. The inner wall of the cylinder may be equipped with a lifting plate or a lifting plate to continuously lift and scatter the material, increase the contact area between the material and the hot air flow, and improve the drying efficiency.

• Heat source system:

Provides heat for the drying process. Common heat sources include coal, natural gas, biomass particles, fuel oil, etc. The hot air flow generated by the heat source enters the drying cylinder through a specific pipe or channel to exchange heat with the material.

• Transmission device:

includes components such as motor, reducer, coupling, and support wheel. The motor provides power and transmits the power to the support wheel through the reducer and coupling. The support wheel drives the drying cylinder to rotate, so that the material continues to roll and move in the cylinder.

• Feeding device:

Responsible for transporting the dry mortar to be dried into the drying cylinder. Generally, it is necessary to ensure the uniformity and stability of the feed so that the subsequent drying process can proceed smoothly.

• Discharging device:

used to discharge the dry mortar after drying, usually with good sealing to prevent hot air leakage and dust overflow.

• Dust removal system:

collect and treat the dust generated during the drying process, reduce environmental pollution, and protect the working environment and the health of operators. Common dust removal equipment includes bag Dust Collectors, cyclone dust collectors, etc.

• Control system:

an automatic control system is used to monitor and control the operating parameters of the drying equipment, such as temperature, speed, feed amount, etc., to ensure the stable operation of the equipment and the drying effect.

• Working principle:

after the wet dry mortar enters the drying cylinder from the feeding device, it is continuously picked up and scattered by the lifting plate or the lifting plate as the cylinder rotates. At the same time, the hot air flow generated by the heat source system enters the cylinder, fully contacts with the material, and performs heat exchange. Under the action of the hot air flow, the moisture in the material gradually evaporates and turns into water vapor to be discharged from the cylinder. After a period of drying, the moisture content of the dry mortar reaches the requirement and is discharged from the discharging device.

Advantages and characteristics of dry mortar drying equipment

High efficiency and energy saving:

• High thermal efficiency:

Advanced structural design and good thermal insulation performance enable the hot air flow to fully contact the material, reduce heat loss and improve thermal efficiency. Compared with traditional drying equipment, it can save a lot of energy consumption.

• Strong fuel adaptability:

According to different production needs and fuel supply conditions, you can choose suitable fuels, such as coal, natural gas, biomass pellets, etc., to reduce fuel costs.

Good drying effect:

• Even material drying:

Through the reasonable cylinder structure and lifting device design, ensure that the material can be evenly heated during the drying process, avoid local overheating or incomplete drying, and ensure the drying quality of dry mortar.

• Precise moisture control:

It can accurately control the moisture content of the dried material, and according to different product requirements, control the moisture content within a suitable range to improve the quality and stability of the product.

Compact structure:

• Small footprint:

Compared with some large drying equipment, the dry mortar drying equipment has a more compact structure and a small footprint, which is suitable for use in production sites with limited space.

• Easy installation:

The overall structure of the equipment is simple, the installation process is relatively easy, and no complex infrastructure and large-scale lifting equipment are required, which can shorten the installation cycle and reduce the installation cost.

Reliable operation:

• Durable equipment:

The use of high-quality materials and advanced manufacturing technology ensures the wear resistance and corrosion resistance of the equipment and extends the service life of the equipment.

• Low maintenance cost:

The equipment operates stably, the failure rate is low, the daily maintenance work is simple, and the maintenance cost is low.

High degree of automation:

• Easy operation:

Equipped with an automatic control system, the operator only needs to set the relevant parameters, and the equipment can run automatically, which greatly reduces the labor intensity and improves production efficiency.

• Convenient monitoring:

It can monitor the operating status of the equipment and various parameters in the drying process in real time, such as temperature, humidity, speed, etc., so that the operator can grasp the operation of the equipment in time and make corresponding adjustments.

Good environmental performance:

• Dust treatment:

Equipped with an efficient dust removal system, it can effectively collect and treat the dust generated during the drying process, reduce dust emissions, and reduce pollution to the environment.

• Exhaust gas emission meets the standard:

Reasonable treatment of the hot air flow makes the exhaust gas emission meet the national environmental protection standards and reduce the impact on the atmospheric environment.

Parameters

Item | Unit | Model | |||

Φ3.2*8.0 | Φ3.6*8.0 | Φ3.8*10.0 | Φ4.0*12.0 | ||

Diameter of outer cylinder | m | 3.2 | 3.6 | 3.8 | 4.0 |

Length of outer cylinder | m | 8.0 | 8.0 | 10.0 | 12.0 |

Cylinder volume | m³ | 64.31 | 81.39 | 113.35 | 150.72 |

Cylinder speed | rpm | 4-10 | |||

The initial moisture content of fly ash | % | 20-25 | |||

Water content of fly ash | % | ≤2 | |||

Max inlet temperature | ℃ | ≤950 | |||

Capacity | T/H | 20-25 | 25-35 | 40-50 | 50-55 |

Motor | Y132-S-4 | Y160-M-4 | Y160-M-4 | Y280-S-4 | |

Power | Kw | 11*4 | 15*4 | 90 | 110 |

Reductor | XWD7-23 | XWD7-23 | ZSY315-‖ | ZSY355-‖ | |

Reductor ratio | 29 | ||||

RELATED

RELATED

RELATED

RELATED

This website uses cookies to ensure you get the best experience on our website.