FGD, which stands for Flue Gas Desulfurization , refers to the technological process used to remove sulfur oxides (SOₓ), primarily sulfur dioxide (SO₂), from the exhaust flue gases of fossil-fuel power plants and other industrial processes .

The core purpose of FGD systems is to mitigate the environmental and health impacts of SO₂ emissions, which are a major contributor to acid rain and atmospheric pollution . This technology is a critical measure for controlling acid rain and SO₂ pollution .

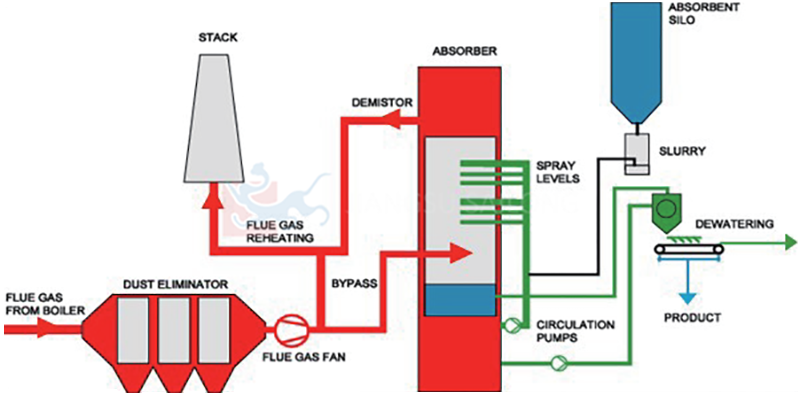

Wet desulfurization process flow chart

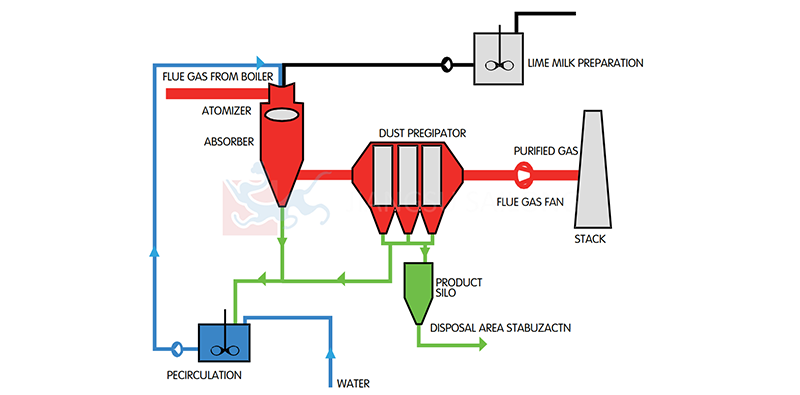

Dry desulfurization process flow chart

Introduction

The Desulfurization Tower is a tower-type equipment for desulfurization of industrial Waste Gas. Desulfurization towers built with granite are widely used. They use the principle of water film desulfurization and dust removal, also known as granite water film desulfurization Dust Collector, or granite water film desulfurization dust collector.

Applications materials of Dust Collector

The advantage is that it is easy to maintain, and different dust removal agents can be prepared to achieve the effects of dust removal and Desulfurization (denitrification) at the same time. With the development of FRP technology, Desulfurization Towers are gradually changed to be made of FRP. Compared with granite desulfurization towers, FRP desulfurization towers have low cost, easy processing, no rust and no rot, and light weight, so they have become the development trend of desulfurization towers in the future. In addition, 316L stainless steel has three advantages of corrosion resistance, high temperature resistance, and wear resistance, which is also one of the important development trends of desulfurization towers.

Flue Gas Desulfurization (FGD) is a critical technology designed to remove sulfur dioxide (SO₂) from exhaust gases generated by industrial processes, particularly fossil fuel combustion in power plants and refineries. SO₂ is a major contributor to acid rain, respiratory illnesses, and environmental degradation, making FGD systems essential for compliance with global emissions regulations and sustainable industrial operations. The history of FGD dates back to the 1850s, but its widespread adoption accelerated in the late 20th century as environmental awareness grew. This article provides a detailed overview of FGD principles, methods, and advancements, aligning with modern SEO standards to address key queries like "FGD SCRubbing," "wet FGD vs. dry FGD," and "SO₂ control technology."

Principles of FGD

FGD systems rely on chemical reactions between alkaline sorbents and acidic SO₂ in flue gas. The most common sorbents include limestone (CaCO₃), quicklime (CaO), hydrated lime (Ca(OH)₂), magnesium hydroxide (MgO), and ammonia (NH₃). These substances neutralize SO₂, converting it into stable compounds like gypsum (CaSO₄·2H₂O) or elemental sulfur. The process can occur via wet, dry, or semi-dry methods, depending on the sorbent state and reaction conditions:

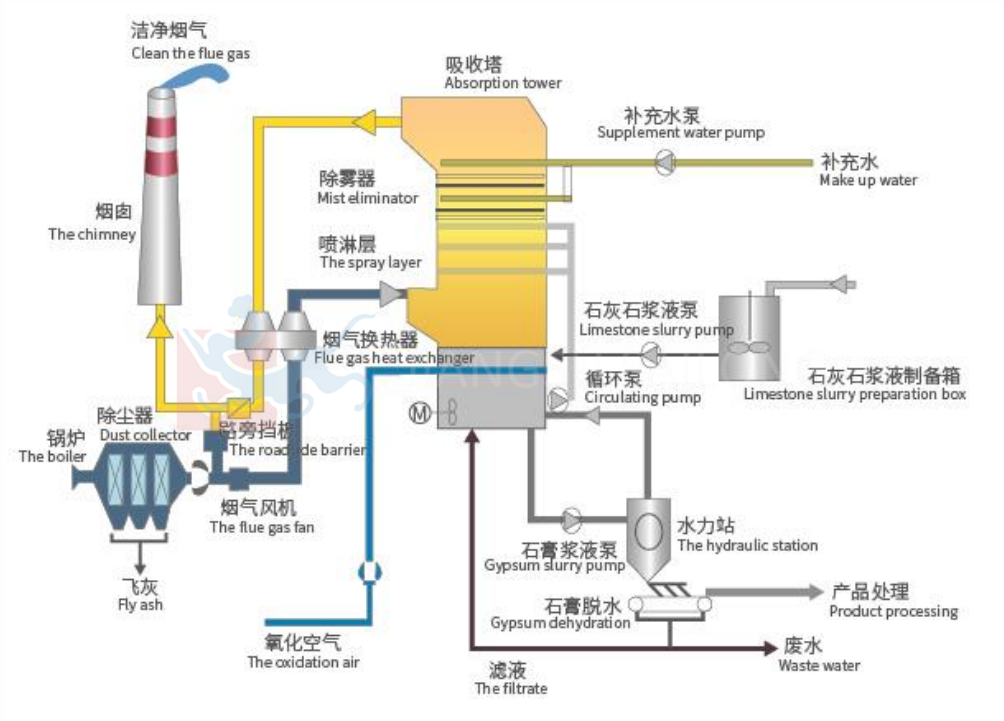

- Wet FGD: Uses alkaline slurries or solutions (e.g., limestone slurry) to absorb SO₂ in a spray tower. This method achieves high efficiency (>95%) and is widely adopted in coal-fired power plants.

- Dry FGD: Involves injecting dry sorbents (e.g., lime powder) into flue ducts, producing a dry byproduct. While cost-effective, it has lower efficiency (70–90%).

- Semi-Dry FGD: Combines wet sorbent injection with dry byproduct recovery, balancing efficiency and cost.

Major FGD Technologies

1. Wet Limestone-Gypsum Method: The dominant FGD technology globally, accounting for over 85% of installations. Limestone slurry reacts with SO₂ to form gypsum, a marketable byproduct for construction materials. Key advantages include high SO₂ removal (>95%) and reliability, though it requires significant water and wastewater management.

2. Spray Dryer Absorption (SDA): A semi-dry method where lime slurry is atomized into flue gas, evaporating to form a dry powder. SDA is suitable for low-sulfur fuels and regions with water scarcity.

3. Circulating Fluidized Bed (CFB) Dry Scrubbing: Uses hydrated lime in a fluidized reactor, achieving 90–97% efficiency. CFB is compact and ideal for retrofit projects.

4. Regenerative Processes: Such as the Wellman-Lord or chelated-iron systems, which recover sulfur or sulfuric acid for reuse. These reduce waste but involve higher operational complexity.

Applications and Environmental Benefits

FGD is extensively deployed in:

- Coal-Fired Power Plants: The largest source of SO₂ emissions.

- Industrial Boilers and Waste Incinerators.

- Shipping Industry: To comply with IMO sulfur caps.

By removing SO₂, FGD mitigates acid rain, reduces PM2.5 formation, and prevents health issues like asthma. Modern systems also co-remove mercury and other heavy metals.

Challenges and Innovations

Despite its efficacy, FGD faces challenges:

- High Energy Consumption: Wet FGD can reduce plant efficiency by 1–2%.

- Byproduct Management: Gypsum quality must meet market standards, while some methods produce less valuable waste.

- Carbon Footprint: Limestone calcination and sorbent production emit CO₂.

Recent innovations focus on optimization tools (e.g., Aspen Plus simulations and CFD modeling) to enhance efficiency and reduce costs. Emerging methods like the chelated-iron process enable high-value sulfur recovery, supporting a circular economy.

Future Trends

FGD systems are evolving to integrate with carbon capture and storage (CCUS) and accommodate hydrogen-enriched fuels. Life cycle assessment (LCA) is increasingly used to evaluate environmental trade-offs, ensuring solutions like seawater FGD or ammonia-based processes align with decarbonization goals.

Applications materials of Dust Collector

The advantage is that it is easy to maintain, and different dust removal agents can be prepared to achieve the effects of dust removal and Desulfurization (denitrification) at the same time. With the development of FRP technology, Desulfurization Towers are gradually changed to be made of FRP. Compared with granite desulfurization towers, FRP desulfurization towers have low cost, easy processing, no rust and no rot, and light weight, so they have become the development trend of desulfurization towers in the future. In addition, 316L stainless steel has three advantages of corrosion resistance, high temperature resistance, and wear resistance, which is also one of the important development trends of desulfurization towers.

This website uses cookies to ensure you get the best experience on our website.