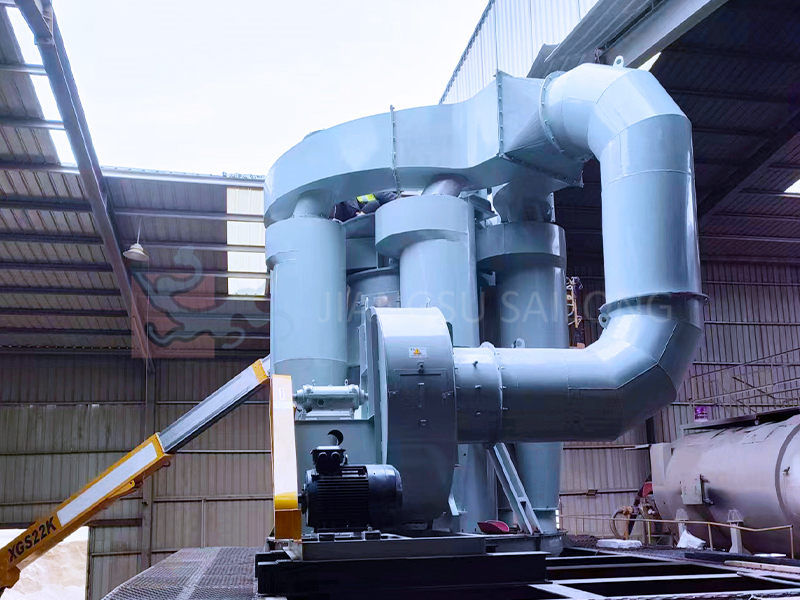

A Powder Separator, designed to separate solid particles from gas streams or classify powders based on size, density, or other properties, finds extensive use across various industries. Its applications are rooted in the need to purify, recover, or grade particulate materials, ensuring operational efficiency, product quality, and environmental compliance. Below are the common uses of powder separators across different sectors:

1. Industrial Dust Collection and Air Pollution Control

Powder separators play a critical role in removing airborne particulate matter from industrial exhaust gases. In manufacturing plants, power stations, and processing facilities, equipment such as cyclone separators, baghouse filters, and electrostatic precipitators are employed to:

- Trap and remove dust, fumes, and smoke particles generated during processes like welding, casting, or material grinding.

- Comply with environmental regulations by reducing particulate emissions, thus preventing air pollution. For example, in cement factories, cyclones and bag filters remove cement dust from the air, protecting both workers and the environment.

- Recover valuable materials from dust, such as metal powders in machining operations or plastic particles in recycling plants, minimizing waste and enhancing cost-effectiveness.

2. Chemical and Petrochemical Industry

In chemical processing, powder separators are essential for:

- Separating catalysts from reaction products. For instance, in fluidized bed reactors, cyclone separators efficiently reclaim catalysts like zeolites, which are costly and reusable.

- Purifying gases by removing solid impurities. During petrochemical refining, separators filter out coke particles or catalyst fines from process gases, ensuring downstream equipment (e.g., compressors or reactors) remains unobstructed.

- Classifying powdered chemicals based on particle size. Sieving or air classifiers are used to separate powders into different fractions for specific applications, such as adjusting the texture of pigments or additives.

3. Food and Pharmaceutical Manufacturing

Quality control and product purity are paramount in these industries, where powder separators serve to:

- Remove foreign particles or agglomerates from powdered ingredients. In flour milling, air classifiers separate fine flour from coarser bran, while in pharmaceutical production, separators ensure active pharmaceutical ingredients (APIs) are free of contaminants.

- Prevent cross-contamination by efficiently separating different powder batches. Bag filters or cyclones are used in spice processing or tablet manufacturing to maintain product integrity.

- Recover valuable powders from production waste. For example, in chocolate or coffee processing, separators reclaim fine particles from exhaust streams, reducing material loss.

4. Mineral Processing and Mining

In mining and mineral extraction, powder separators facilitate:

- Ore beneficiation by separating valuable minerals from waste rock. Air classifiers or electrostatic separators are used to sort minerals like quartz, feldspar, or mica based on density or electrical properties.

- Coal preparation plants employ cyclones to remove ash and impurities from pulverized coal, improving combustion efficiency in power generation.

- Dust control in mineral crushing and grinding operations, where separators capture fine particles to prevent respiratory hazards for workers and comply with safety standards.

5. Plastic and Polymer Processing

The plastics industry utilizes powder separators to:

- Recycle plastic powders by separating different polymer types or removing contaminants. Electrostatic separators can distinguish between plastics like PVC and PET based on charge properties.

- Classify plastic granules or powders for specific applications, such as adjusting particle size for 3D printing filaments or injection molding.

- Collect plastic fines generated during extrusion or pelletizing processes, reducing waste and maintaining equipment cleanliness.

6. Agriculture and Feed Processing

In agricultural applications, separators are used to:

- Grade grains or seeds by size and density. Air classifiers remove chaff, weeds, or broken kernels from crops like wheat or soybeans, ensuring uniform quality for storage or processing.

- Process animal feed by separating fine powders from coarser particles, preventing dust explosions and ensuring feed consistency. Cyclones and filters also capture dust from feed milling operations to maintain a safe working environment.

7. Powder Coating and Surface Treatment

In the coating industry, powder separators:

- Recover and recycle oversprayed powder coatings during electrostatic spraying processes. Cyclone separators or cartridge filters capture unused powder, which can be reclaimed for reuse, reducing material costs and waste.

- Maintain coating quality by removing over-cured or agglomerated particles from the powder stream, ensuring a smooth and uniform finish on products like automotive parts or appliances.

8. Construction and Building Materials

For materials like cement, (gypsum), or concrete additives, separators:

- Classify powdered materials to meet specific grade requirements. For example, cement mills use air classifiers to separate fine cement particles from coarser clinker, adjusting the fineness to meet ASTM or ISO standards.

- Control dust emissions during concrete batching or asphalt production, using baghouse filters to prevent particulate release into the atmosphere.

9. Energy Production

In power generation and renewable energy sectors:

- Coal-fired power plants use electrostatic precipitators and bag filters to remove fly ash from Flue Gases, reducing emissions and recovering ash for use in construction materials (e.g., concrete additives).

- Biomass energy facilities employ cyclones to separate wood chips or sawdust from combustion gases, ensuring efficient fuel utilization and minimizing particulate emissions.

10. Research and Laboratory Settings

In scientific research, compact powder separators (e.g., centrifugal or micro-cyclones) are used for:

- Particle size analysis and characterization, helping researchers study powder behavior in fields like materials science or aerosol physics.

- Small-scale material separation for experiments, such as isolating specific particle fractions for toxicity testing or formulation development.

Conclusion

Powder separators are indispensable across industries, serving dual purposes of enhancing product quality and ensuring environmental and operational safety. Their applications range from pollution control and material recovery to precise particle classification, reflecting their versatility in addressing both industrial needs and sustainability goals. By efficiently separating powders, these systems optimize processes, reduce waste, and contribute to the production of high-purity materials essential for modern manufacturing.

This website uses cookies to ensure you get the best experience on our website.

Comment

(0)